Twin Screw Extruder Underwater Pelletizing Granulator Making Machine for Plastic Recycling TPU/TPR/EVA etc

China Twin Screw Extruder Underwater Pelletizing Granulator Making Machine for Plastic Recycling TPU/TPR/EVA etc, Find details about China TPU Underwater Pelletizing Line, TPU Underwater Extruder from Twin Screw Extruder Underwater Pelletizing Granulator Making Machine for Plastic Recycling TPU/TPR/EVA etc - Nanjing Kerke Extrusion Equipment Co., Ltd.

Description

Basic Info

- Model NO.: KTE-75B

- Plastic Processed: PP PE PC ABS Pet PA EVA TPU TPR TPE

- Feeding Mode: One or Multiple Feed

- Screw: Twin-Screw

- Screw Channel Structure: Deep Screw

- Automation: Automatic

- Application: Plastic Granules

- Capacity: 300~800kg/H

- Screw Diameter: 71mm

- Elements Material: W6mo5cr4V2

- Inverter Brand: Delta

- Trademark: Kerke

- Specification: 20" or 40" Container

- HS Code: 8477201000

- Type: Twin Screw Extruder

- Product Type: Granulating Extruder

- Assembly Structure: Integral Type Extruder

- Engagement System: Intermeshing

- Exhaust: Exhaust

- Computerized: Computerized

- Motor: 132kwac

- Screw Speed: 600rpm

- L/D: 40:1

- Motor Brand: Siemens

- Certificate: ISO Ce SGS TUV BV

- Transport Package: Wooden Cases or Customizable

- Origin: Nanjing, China

Product Description

Welcome To Kerke Extrusion - High Cost-Effective Extruder Manufacturer !

Nanjing Kerke Extrusion Equipment Co., Ltd. is a High-Tech company, which is composed of well-experienced team in R & D design, manufacturing technique, sales service and bases on twin screw extruder industry more than 10 years.

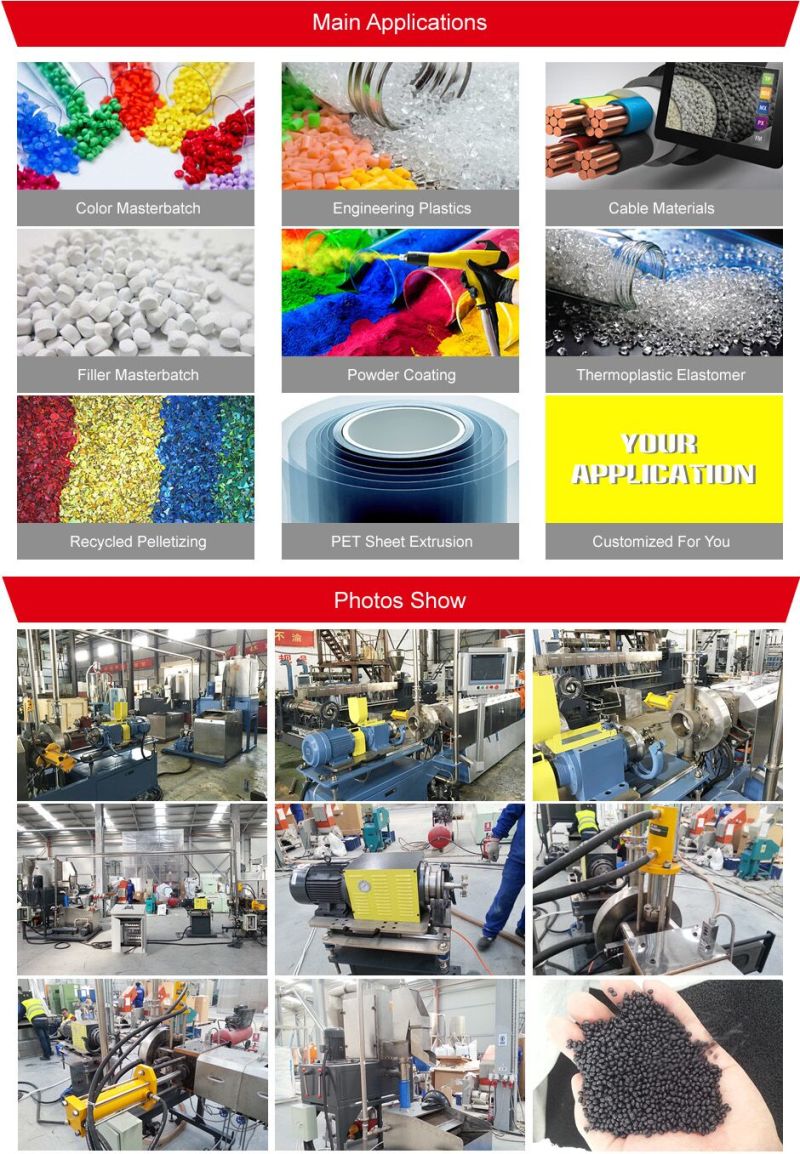

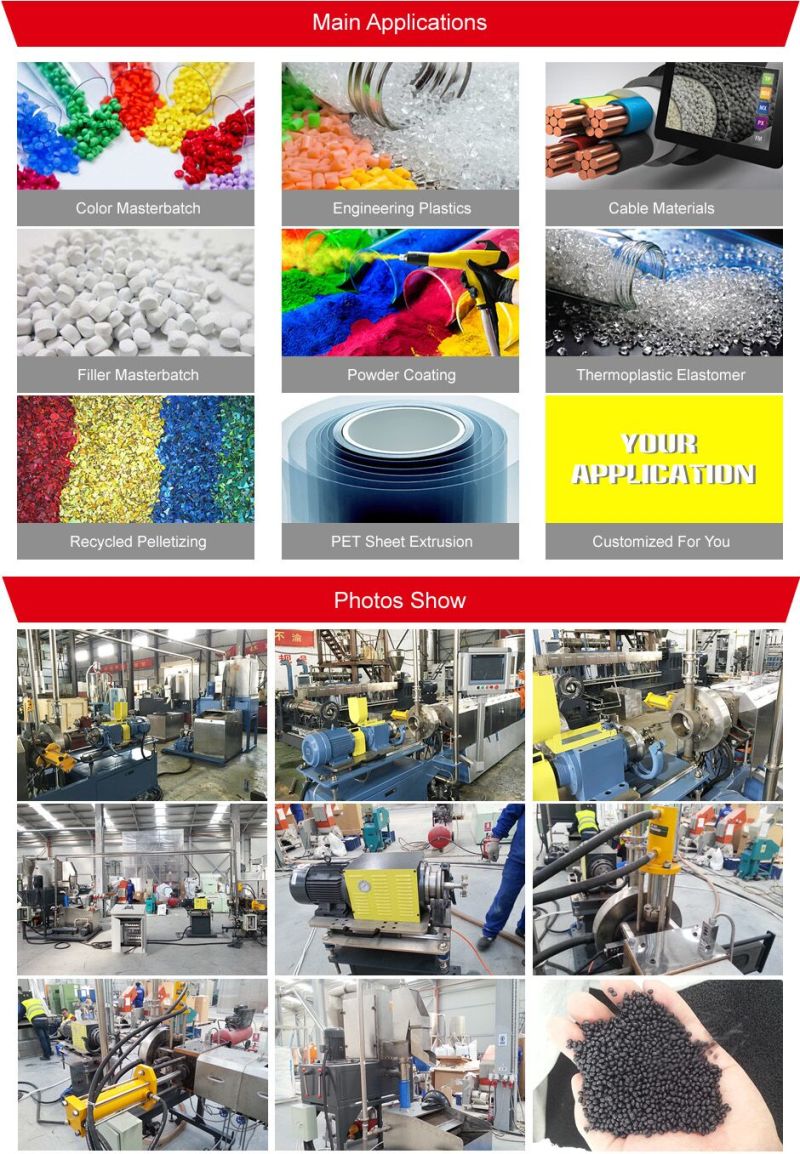

Our production series contain single screw extruder, co-rotating twin-screw compounding extruder KTE B series from KTE-20B to KTE-95B, KTE D series from KTE-36D to KTE-95B,KTE/SE two-stage compounding line,KUW Underwater series from KUW-36D to KUW-95D, auxiliary equipment etc.

Why Choose Kerke Extrusion ?

Website:

Youtube:

Nanjing Kerke Extrusion Equipment Co., Ltd. is a High-Tech company, which is composed of well-experienced team in R & D design, manufacturing technique, sales service and bases on twin screw extruder industry more than 10 years.

Our production series contain single screw extruder, co-rotating twin-screw compounding extruder KTE B series from KTE-20B to KTE-95B, KTE D series from KTE-36D to KTE-95B,KTE/SE two-stage compounding line,KUW Underwater series from KUW-36D to KUW-95D, auxiliary equipment etc.

Why Choose Kerke Extrusion ?

- Focus on twin screw extruder

- Over 60 countries customers

- Only sell the most suitable line to customers

- Produce all parts by our factory

- 20% rising every year

- 95% customer satisfaction

- More than 60 energetic and hardworking employees

| Model | D (mm) | L/D | N (r/min) | P (KW) | Q (kg/h) | |

| KTE-20B | 21.7 | 28~40 | 600 | 4/4.5 | 3~15 | |

| KTE-36 | B | 35.6 | 28~60 | 500/600 | 18.5/22 | 20~100 |

| D | 35.6 | 28~60 | 800 | 22/37 | 110~200 | |

| KTE-50 | B | 50.5 | 28~60 | 400/500/600 | 45/55/75 | 120~280 |

| D | 50.5 | 28~60 | 800 | 55/75 | 225~375 | |

| KTE-52B | 51.4 | 28~60 | 400/500/600 | 45/55/75 | 120~280 | |

| KTE-65 | B | 62.4 | 28~60 | 400/500/600 | 90/110 | 200~500 |

| D | 62.4 | 28~60 | 800 | 55/75 | 350~600 | |

| KTE-75 | B | 71 | 28~60 | 400/500/600 | 110/132/160 | 300~800 |

| D | 71 | 28~60 | 800 | 160/220 | 500~1000 | |

| KTE-85B | 81 | 28~60 | 400/500/600/ | 160/220/280 | 480~1000 | |

| KTE-95B | 93 | 28~60 | 400 / 500/600 | 250 /280/ 315 | 750~1400 | |

Website:

Youtube: